Explore the Latest CNC Milling Machine - Revolutionizing Small-Scale Machining

By:Admin

Introduction:

In today's fast-paced world, precision manufacturing plays a pivotal role in various industries, from aerospace and automotive to electronics and medical equipment. With the ever-increasing demand for intricately designed and flawlessly executed components, companies are constantly seeking innovative tools that offer enhanced precision and efficiency. One such ground-breaking solution is the cutting-edge mini CNC milling machine, produced by a renowned industry-leading company. This article delves into the features, benefits, and the impact of this state-of-the-art equipment in revolutionizing precision manufacturing processes.

Feature Highlights:

The mini CNC milling machine developed by the company harnesses cutting-edge technology to deliver exceptional precision and versatility. Equipped with advanced computer numerical control (CNC), this machine allows for automated control and precise three-dimensional (3D) milling operations. The compact design enables it to fit seamlessly into various manufacturing environments, including small workshops and research labs.

Enhanced Accuracy:

Designed with meticulous attention to detail, the mini CNC milling machine offers unparalleled accuracy in the manufacturing process. The integration of innovative servo control systems ensures precise movement of the spindle and worktable, resulting in superior finished products with minimal errors or rework. This level of precision opens new avenues for manufacturers who strive for excellence in their craftsmanship.

Versatility in Material Machining:

The versatility of the mini CNC milling machine is a game-changer in precision manufacturing. Its robust structure allows for the machining of various materials, including metals, plastics, and composites. This adaptability enables companies to streamline production processes by consolidating multiple machining tasks into a single machine. With the ability to handle a wide range of materials, businesses can save time, reduce costs, and enhance overall efficiency.

User-Friendly Interface:

Understanding the importance of user experience, the company has developed an ergonomic and intuitive interface for the mini CNC milling machine, ensuring ease of operation for personnel at any skill level. The user-friendly control panel offers extensive functionalities, such as tool path visualization, parameter adjustments, and real-time monitoring, empowering operators to optimize operations and maintain productivity. Additionally, the machine's compatibility with various design software allows seamless integration into existing manufacturing workflows.

Improved Production Speed:

The mini CNC milling machine's state-of-the-art technology enables faster production cycles without compromising precision. Utilizing high-speed spindles and advanced cutting tools, the machine increases throughput while maintaining excellent surface finish quality. Manufacturers can meet tighter deadlines and cater to customer demands more efficiently, granting them a competitive edge in the market.

Revolutionizing Precision Manufacturing:

The introduction of the mini CNC milling machine has transformed the landscape of precision manufacturing, offering numerous benefits across industries. For aerospace manufacturers, it enables the production of intricate components with perfect tolerances, contributing to safer and more efficient aircraft. Automotive companies can benefit from its streamlined workflows, resulting in higher-quality parts and improved vehicle performance. Further, the medical industry can leverage the precision of this machine to manufacture critical implants, prosthetics, and surgical instruments, ensuring better patient outcomes.

Conclusion:

The innovative mini CNC milling machine, developed by the renowned industry-leading company, has revolutionized precision manufacturing across diverse sectors. With its exceptional accuracy, material versatility, user-friendly interface, increased production speed, and numerous other cutting-edge features, this advanced machinery sets new standards in the industry. As demands for superior quality and efficiency continue to rise, the mini CNC milling machine stands as a testament to the pursuit of excellence through technological innovation.

Company News & Blog

Revolutionary 3D Wood Cutting CNC Machine Takes Woodworking to the Next Level

Title: Revolutionary 3D Wood Cutting CNC Machine Unveiled by Innovators in Precision WoodworkingIntroduction:[date], [location] - Today, [Company Name] is proud to introduce their groundbreaking 3D Wood Cutting CNC Machine, a game-changer in the world of precision woodworking. This state-of-the-art technology aims to revolutionize the industry by providing woodworkers with unparalleled accuracy, speed, and efficiency in their craft. By seamlessly integrating advanced CNC technology, [Company Name] has created a versatile machine that can unlock endless possibilities in woodworking.Cutting-Edge Features:The 3D Wood Cutting CNC Machine incorporates cutting-edge features that enable users to achieve precise cuts swiftly and effortlessly. Its robust design ensures stability and durability, even during heavy-duty applications. Equipped with a powerful spindle that delivers high torque, this machine can effortlessly cut through various types of wood, including hardwoods, softwoods, and even composites. Its impressive cutting speed and accuracy allow for intricate designs and complex shapes to be achieved with ease.Furthermore, the machine is equipped with advanced computer-controlled software that offers a user-friendly interface. This software enables woodworkers to digitize their ideas and designs, translating them into perfected creations. The 3D Wood Cutting CNC Machine allows for flawless execution, ensuring that woodworkers are able to transform their visions into reality.Unparalleled Precision:One of the most remarkable aspects of [Company Name]'s 3D Wood Cutting CNC Machine is its unparalleled precision. By utilizing advanced laser scanning technology, the machine is capable of capturing intricate details and contours of any wood piece. This enables woodworkers to reproduce complex patterns and designs flawlessly. With the ability to achieve detailed cuts as small as 0.1mm, this machine offers exceptional precision and accuracy that was previously unimaginable.User-Friendly Interface and Software:The 3D Wood Cutting CNC Machine comes with a user-friendly interface and software that simplifies the operation for both seasoned professionals and novice woodworkers. Its intuitive design ensures ease of use, making it accessible to woodworkers of all skill levels. The software also allows for easy customization and modifications, making it convenient to adapt designs on the fly without any hassle.Efficiency and Time-Saving Capabilities:By automating the woodworking process, [Company Name]'s 3D Wood Cutting CNC Machine significantly improves efficiency and saves valuable time. Traditional woodworking techniques are labor-intensive and time-consuming, often requiring meticulous handiwork. This revolutionary machine eliminates the need for manual labor, reducing the production time significantly. Additionally, its ability to perform complex cuts effortlessly allows for an increase in productivity, ultimately resulting in a higher output and increased profits for woodworkers.Environmental Consciousness:In addition to its precision and efficiency, the 3D Wood Cutting CNC Machine also promotes environmental consciousness. Designed to minimize waste production, this machine maximizes material utilization and reduces the environmental impact associated with traditional woodworking methods. By eliminating human errors and optimizing material usage, this technology reduces the need for excess materials, making it an eco-friendly choice.Conclusion:[Company Name]'s groundbreaking 3D Wood Cutting CNC Machine represents a turning point in the woodworking industry. With its exceptional precision, efficiency, and time-saving capabilities, this innovative technology sets a new standard for precision woodworking. Craftsmen and professionals alike now have the tools to bring their creative visions to life seamlessly, pushing the boundaries of traditional woodworking. As [Company Name] continues to revolutionize the industry, it is evident that the future of precision woodworking lies in the hands of their 3D Wood Cutting CNC Machine.

Discover the Latest Innovation: Advanced Laser Technology for Rust Removal

Title: Revolutionary Laser Technology Offers Effective Rust Removal SolutionIntroductionIn today's fast-paced world, technology continues to evolve rapidly, solving various problems that were once considered difficult or impossible to address. One such innovation is the Laser Paint Rust Remover, a groundbreaking solution designed to combat the persistent issue of rust. Developed by a reputable company in the industry, this futuristic technology holds incredible potential in providing efficient rust removal solutions for diverse applications.BodyParagraph 1: Understanding the Persistent Rust ProblemRust is a common and persistent issue faced by industries and individuals alike. It damages metal components, diminishes structural integrity, and reduces the overall lifespan of various objects. Traditional rust removal methods often involve time-consuming procedures, chemical use, and physical effort. However, the Laser Paint Rust Remover promises to revolutionize rust removal by offering a quicker and more effective solution.Paragraph 2: The Groundbreaking Laser TechnologyThe Laser Paint Rust Remover is a state-of-the-art invention that employs innovative laser technology to eliminate rust effectively, without causing any damage to the underlying metal surface. It utilizes a high-energy laser beam to remove rust and paint coating from metal surfaces, leaving them clean and ready for further treatment. This technology ensures precision, accuracy, and significant time-saving benefits, catering to both industrial and individual needs.Paragraph 3: How Laser Paint Rust Remover WorksThe Laser Paint Rust Remover operates on a two-step process: rust removal and paint stripping. Firstly, the laser beam focuses on the rust-infected area, generating intense heat that vaporizes the rust particles, converting them into gas. This process effectively removes rust from the metal surface. Subsequently, the laser beam continues its operation, stripping away any paint coatings or surface contaminants.Paragraph 4: Advantages and BenefitsThe Laser Paint Rust Remover provides several advantages compared to traditional rust removal methods. The key benefits include:1. Non-Invasive and Environmentally-Friendly: Unlike chemical treatments, the laser technology ensures the rust removal process is non-invasive and does not produce hazardous waste or fumes. It also eliminates the need for physical force, reducing the risk of metal surface damage.2. Enhanced Precision: The laser beam's high precision allows for accurate and selective rust removal. This is particularly beneficial when working with intricate metal components or fragile surfaces that require delicate handling.3. Time and Cost-Efficient: The laser technology significantly speeds up the rust removal process, saving both time and labor costs. With its ability to precisely target rust-infected areas, it minimizes the need for complete refinishing of larger surfaces.Paragraph 5: Applications of Laser Paint Rust RemoverThe Laser Paint Rust Remover has a wide range of applications across multiple industries, including:1. Automotive Industry: Effective in removing rust from cars, trucks, and other vehicles, this technology can prolong their lifespan and enhance their aesthetic appeal.2. Construction and Infrastructure: Rust removal in buildings, bridges, and other structural components is essential for maintaining their structural integrity. The Laser Paint Rust Remover ensures thorough and efficient rust removal.3. Manufacturing Sector: Metal equipment and machinery are prone to rust damage. The laser technology offers a reliable solution for removing rust from various industrial apparatus, aiding in smooth production processes.ConclusionThe Laser Paint Rust Remover is set to revolutionize the rust removal industry with its cutting-edge laser technology. Its non-invasive, precise, and efficient nature offers a superior alternative to traditional rust removal techniques. As it continues to gain traction in various sectors, this innovative solution has the potential to extend the lifespan of metal objects, reduce maintenance costs, and improve overall efficiency.

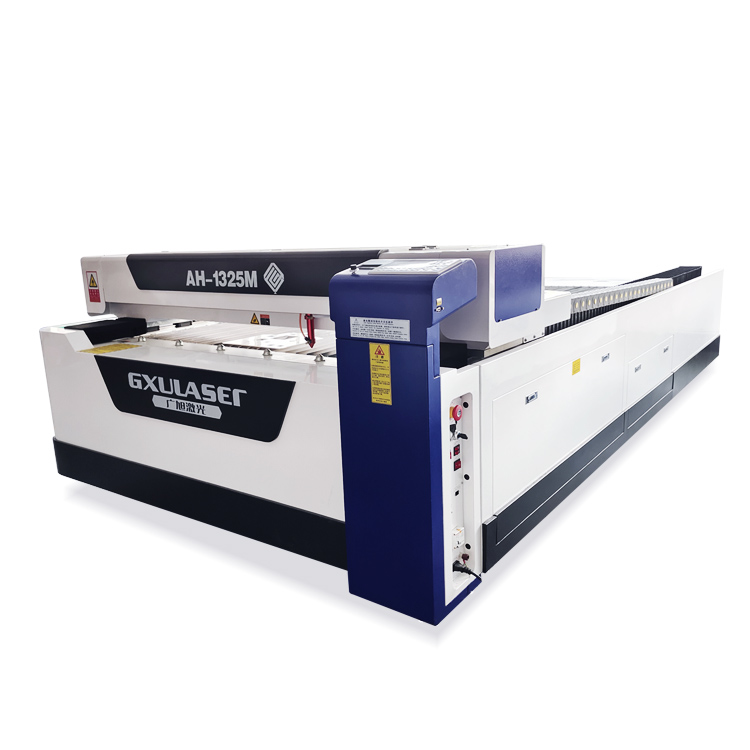

Optimize Production Efficiency with Advanced CNC Laser Technology

Industrial CNC Laser: Revolutionizing Precision Cutting and EngravingIn a world where precision and efficiency are of utmost importance, Industrial CNC Laser has emerged as a leading provider of cutting-edge laser technology. With their advanced machinery and unwavering commitment to innovation, this company has revolutionized the fields of manufacturing, engraving, and fabrication.Founded in [year], Industrial CNC Laser has been at the forefront of laser technology, offering a wide range of cutting-edge solutions to meet the diverse needs of industries worldwide. With an extensive product lineup and a team of highly skilled professionals, the company has established itself as a trusted provider of industrial laser systems.One of the primary strengths of Industrial CNC Laser lies in its commitment to research and development. The company invests heavily in cutting-edge technology, ensuring their equipment remains at the forefront of innovation. By staying up-to-date with the latest advancements in laser technology, Industrial CNC Laser continually offers their clients the most advanced and efficient solutions.The flagship product offered by Industrial CNC Laser is its state-of-the-art CNC laser cutting machine. These machines are designed to deliver precise and accurate results, making them an indispensable tool across various industries. With the ability to cut materials such as metal, wood, plastic, and even stone, these machines enable businesses to achieve intricate designs and shapes with ease.The CNC laser cutting machines offered by Industrial CNC Laser combine speed, accuracy, and versatility. Equipped with high-powered laser beams guided by advanced software, these machines can achieve intricate cuts, ensuring clean edges and precise dimensions. This level of precision eliminates the need for additional finishing processes, saving businesses both time and money.Moreover, Industrial CNC Laser understands the importance of customization in today's competitive market. They offer a range of options to tailor their machines to the specific needs of each client. Whether it's the size of the cutting bed, the power of the laser, or the software capabilities, Industrial CNC Laser ensures that their machines can be customized to meet the unique requirements of any project.In addition to CNC laser cutting machines, Industrial CNC Laser also provides a range of engraving systems. These finely tuned machines can engrave intricate designs and patterns on various materials, including glass, wood, plastic, and metal. With their precise laser technology, these engraving systems enable businesses to personalize their products, create intricate artwork, and add branding elements with utmost accuracy.What sets Industrial CNC Laser apart from its competitors is not only the quality of their machines but also their commitment to customer satisfaction. The company provides comprehensive training, technical support, and maintenance services to ensure their clients can maximize the performance and longevity of their equipment. This customer-centric approach has earned Industrial CNC Laser a loyal and satisfied customer base.As the demand for precision cutting and engraving increases, Industrial CNC Laser remains at the forefront of the industry, consistently pushing the boundaries of what laser technology can achieve. Their commitment to innovation, customization, and customer satisfaction has solidified their position as a global leader in the field.In conclusion, Industrial CNC Laser has made significant strides in revolutionizing the precision cutting and engraving industry. With their advanced CNC laser cutting machines and engraving systems, the company has empowered businesses across various sectors to achieve new levels of precision, efficiency, and customization. As technology continues to evolve, Industrial CNC Laser is poised to maintain its position as an industry leader, delivering cutting-edge solutions to businesses worldwide.

Cutting Edge 3D Wood CNC Machine for Precision Woodworking

Introducing Innovative 3D Wood Cutting CNC Machine Revolutionizing the IndustryWoodworking has been an essential craft for centuries, and with the advancement of technology, the industry has witnessed significant improvements. [Company Name], an innovative leader in manufacturing machinery, is now introducing an extraordinary 3D Wood Cutting CNC Machine that is set to revolutionize the woodworking industry. This cutting-edge machine promises exceptional precision, efficiency, and versatility, making it a must-have tool for woodworkers of all levels.The 3D Wood Cutting CNC Machine is a state-of-the-art device that combines the latest advancements in computer numerical control (CNC) technology with woodcutting capabilities. This machine allows woodworkers to create intricate designs and shapes on various wood types with unparalleled precision and speed. Whether it’s crafting detailed furniture, ornate decorations, or personalized signage, this machine opens up a world of possibilities for woodworkers.The main highlight of this machine is its ability to offer three-dimensional cutting capabilities, revolutionizing the traditional two-dimensional woodcutting process. With this new feature, woodworkers can transform their projects into stunning three-dimensional works of art. The precision and intricate detailing enabled by this machine are unparalleled, ensuring a flawless finish every time.Another outstanding feature of this CNC machine is its user-friendly interface and easy setup process. Advanced software integrated into the machine allows users to design their projects digitally before executing them with precision. This software provides tools for customizing designs, adjusting dimensions, and even importing designs from external sources. With just a few clicks, users can transform their ideas into digital realities and bring them to life through woodcutting.Efficiency is a crucial aspect of any woodworking project, and this machine addresses that need perfectly. The 3D Wood Cutting CNC Machine is designed to minimize material waste, ensuring optimal utilization and cost-effectiveness. Its precise cutting mechanism ensures that every piece of wood is utilized effectively, reducing both time and the requirement for additional materials. This efficiency provides woodworkers with a competitive edge, enabling them to take on more projects and deliver them in shorter time frames.Furthermore, this CNC machine offers a wide range of compatibility with various wood types, including softwoods, hardwoods, and engineered woods. It can seamlessly cut through thick and thin wood sheets, maintaining the same level of precision throughout. This versatility eliminates the need for different machines for different materials, making it an ideal investment for woodworking businesses looking to streamline their operations.In addition to its extraordinary features, [Company Name] provides exceptional after-sales support and training to customers. Their team of experts offers comprehensive training on operating the machine, utilizing the digital design software, and troubleshooting common issues. This ensures that woodworkers can maximize the machine's potential and overcome any challenges they may face along the way.With its innovative design, precision, versatility, and efficiency, the 3D Wood Cutting CNC Machine from [Company Name] is set to redefine the woodworking industry. Whether you are a seasoned professional or an amateur woodworker, this machine is a game-changer that enables you to explore your creativity and bring your designs to life. Invest in this cutting-edge technology to enhance your woodworking capabilities and take your projects to new heights.

Discover the Benefits of a High-Quality Laser Engraver for Woodworking Projects

Title: Innovative Wood Laser Engraver Revolutionizes Precision Product MarkingIntroduction:(Date) - (City, State) - With unparalleled precision and cutting-edge technology, (Company Name), a leading manufacturing company in the laser engraving industry, has recently unveiled its latest innovation - a high-performing Wood Laser Engraver. This advanced engraving machine is poised to revolutionize wood product marking, offering businesses a sustainable and efficient solution for personalized branding and intricate designs. With its diverse capabilities and state-of-the-art features, the Wood Laser Engraver is set to bring a new level of quality and customization to the wood product market.Unleashing Cutting-Edge Technology:Designed with meticulous attention to detail, the Wood Laser Engraver incorporates cutting-edge technology to deliver superior performance. Equipped with a high-powered laser, this engraver provides precision engraving solutions, ensuring accuracy and sharpness in every mark. The machine's advanced software enables businesses to effortlessly create intricate designs, logos, and even photographs, adding a touch of elegance and professionalism to their products.Versatility Redefined:The Wood Laser Engraver redefines versatility, providing businesses with the freedom to etch their desired designs on a wide range of wooden surfaces. From hardwood furniture to delicate wooden accessories, this engraver accommodates the uniqueness and intricacy of various wooden products. Its design versatility makes it an ideal choice for industries such as furniture, interior design, gifting, and art.Sustainable Solution:In today's environmentally conscious world, the Wood Laser Engraver sets itself apart as a sustainable solution for product marking. Operating without the need for physical contact, the laser engraving process eliminates the use of inks, dyes, or harmful chemicals. By utilizing a laser beam focused solely on the desired wooden surface, the engraver ensures minimal waste, reducing both the environmental impact and manufacturing costs for businesses.Efficiency and Time Management:Recognizing the importance of streamlined operations and time management for businesses, (Company Name) has integrated advanced features into the Wood Laser Engraver. With its high-speed laser engraving capabilities, the machine significantly reduces production time, allowing businesses to meet increasing demands effortlessly. Its user-friendly interface enables operators to efficiently operate the machine, optimize production workflows, and minimize downtime, further enhancing productivity and profitability.Unprecedented Precision and Quality:The Wood Laser Engraver sets new standards in precision and quality engraving, ensuring that every mark is clear, legible, and visually appealing. Adopting advanced laser technology, the engraver guarantees consistent results in every engraving cycle, regardless of complex designs or intricate patterns. This precision and clarity enhances the aesthetic appeal of wooden products, setting them apart in a competitive market.Customization and Personalization:Recognizing the growing consumer demand for personalization, the Wood Laser Engraver empowers businesses to offer customized products that resonate with their customers. Whether it's engraving a name, unique design, or even a heartfelt message, the engraver adds a touch of personalization to each wooden product. By embracing this level of customization, businesses can create memorable experiences for their customers, fostering loyalty and brand recognition.Future Developments and Market Impact:The release of the Wood Laser Engraver represents an exciting milestone for (Company Name), highlighting their commitment to innovation and customer satisfaction. With its vast potential, this wood engraving machine is poised to revolutionize the wood product market. Its versatility, precision, and sustainable features make it an attractive choice for businesses seeking to elevate their branding and product offerings.Conclusion:(Company Name)'s pioneering Wood Laser Engraver signifies a transformative milestone in the wood engraving industry. By combining cutting-edge technology, sustainability, and versatility, this advanced machine offers businesses a powerful tool for enhancing their products with precision marks, intricate designs, and a touch of personalization. As (Company Name) continues to innovate, this engraver promises to leave an indelible mark on the wood product market, empowering businesses to deliver exceptional quality and captivating experiences.

Revolutionizing Industrial Marking: Discover the Power of Handheld Laser Marking Machines

Handheld Laser Marking Machine Revolutionizes Product Identification In today's rapidly evolving business landscape, it has become increasingly important for companies to have a reliable and efficient method of product identification. Traditionally, mechanical engraving and inkjet printing have been the go-to methods for marking products. However, these methods are often time-consuming, inefficient, and lack the precision required for modern manufacturing processes. Addressing these challenges, an innovative solution has emerged in the form of handheld laser marking machines. Offering unprecedented flexibility and ease of use, these machines are revolutionizing the way manufacturers mark their products. By harnessing the power of lasers, they provide a permanent and high-quality marking solution that meets the growing demands of various industries.At the forefront of this technological breakthrough is [Company Name], a leading manufacturer and provider of laser marking solutions. With a proven track record of delivering cutting-edge products, [Company Name] has developed a state-of-the-art handheld laser marking machine that is set to redefine product identification standards.The key advantage of the [Company Name]'s handheld laser marking machine lies in its portability and versatility. Unlike traditional marking methods, which often require bulky equipment and time-consuming setups, this handheld device offers unmatched convenience and ease of use. Its ergonomic design ensures comfortable handling, enabling operators to mark products with precision and efficiency.The handheld laser marking machine from [Company Name] employs advanced laser technology, allowing it to mark a wide range of materials with precision and clarity. From metals and plastics to ceramics and glass, this device can produce permanent markings that are resistant to wear, fading, and environmental factors. This robust marking quality ensures that product identification remains intact throughout the product's lifecycle, bolstering traceability and brand integrity.Furthermore, the handheld laser marking machine offers superior speed and efficiency, making it an ideal tool for high-volume production lines. Its cutting-edge laser system enables quick marking times, significantly reducing production bottlenecks and enhancing workflow efficiency. This feature is particularly crucial in industries where fast-paced manufacturing processes are a priority, such as automotive, electronics, and pharmaceuticals.Additionally, [Company Name]'s handheld laser marking machine is equipped with intuitive software that allows for seamless integration with existing production systems. This software enables operators to create and edit marking patterns, texts, barcodes, and graphics directly from their computer. The machine's compatibility with various file formats ensures hassle-free customization, giving manufacturers the freedom to showcase their brand logos and comply with regulatory requirements.Moreover, this handheld device incorporates advanced safety features to protect both operators and the environment. It includes an integrated ventilation system that effectively removes fumes and particles generated during the marking process, ensuring a clean and safe working environment. Additionally, it comes equipped with various safety interlocks and indicators to prevent accidents and ensure user-friendly operation.As the demand for product identification continues to grow in industries such as aerospace, medical devices, and jewelry, [Company Name]'s handheld laser marking machine is poised to become an indispensable tool for manufacturers worldwide. By offering unparalleled precision, portability, and efficiency, it is revolutionizing the product identification landscape.Through their commitment to innovation and customer satisfaction, [Company Name] is establishing itself as a market leader in laser marking technology. With a comprehensive range of solutions tailored to meet the specific needs of different industries, they are empowering manufacturers to remain competitive in an ever-changing market.In conclusion, the handheld laser marking machine from [Company Name] represents a significant advancement in product identification technology. With its portability, versatility, speed, and safety features, it is transforming the way manufacturers mark their products. As businesses strive to enhance traceability and maintain brand integrity, this innovative solution is redefining the standards of product identification in various industries.

Cut Through Metal With Precision: Explore the Power of Fiber Laser Cutters

Fiber Laser Cutter for Metal Revolutionizing Industrial Cutting ProcessesIn recent years, technological advancements have transformed various industries, facilitating efficient, precise, and cost-effective solutions. In the field of metal cutting, the introduction of fiber laser cutter machines has revolutionized industrial processes, ushering in a new era of efficiency and productivity. These cutting-edge machines are now widely adopted by companies across the globe, including the renowned industry leader - [Company Name].[Company Name] is a pioneering force in the field of laser cutting technology, renowned for their cutting-edge solutions and unmatched quality. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted global provider of industrial laser cutting equipment.The utilization of fiber laser technology in metal cutting is a major breakthrough due to its high efficiency, precision, and versatility. Fiber lasers leverage a specially designed optical fiber that maximizes the laser beam quality, resulting in extremely accurate and consistent cutting performances. These lasers are capable of cutting various metals, including stainless steel, aluminum, copper, and brass, with exceptional precision and smooth edges, eliminating the need for additional finishing processes.One of the standout features of [Company Name]'s fiber laser cutter machines is their remarkable speed and efficiency. With an impressive cutting speed that surpasses traditional CO2 laser cutters by up to three times, these machines significantly reduce downtime, allowing companies to handle large production volumes with ease. Moreover, the fiber laser cutter machines maintain their high cutting speeds even when working with complex designs or thicker materials, ensuring uninterrupted workflow and enhanced productivity.In addition to speed, these machines offer exceptional precision and accuracy. The concentrated and intense laser beam from the fiber laser minimizes the heat-affected zone on the material, ensuring clean and high-quality cuts. The advanced control systems integrated into [Company Name]'s machines enable precise control over cutting parameters, making it possible to achieve intricate designs with utmost accuracy. This precision not only optimizes material usage but also minimizes waste, resulting in cost savings and increased profitability for businesses.Furthermore, the fiber laser cutter machines are more energy-efficient than their CO2 counterparts. Operating on significantly lower power consumption, these machines contribute to reduced carbon footprints, aligning with sustainable manufacturing practices. The decreased power consumption also translates to cost savings for businesses in the long run, making it a win-win situation for both the environment and the company's bottom line.[Company Name]'s fiber laser cutter machines also boast notable user-friendly features, allowing both experienced operators and novices to utilize the technology seamlessly. The machines are equipped with intuitive controls, enabling easy adjustments of cutting parameters, such as speed and power, to meet specific project requirements. The user-friendly interface enhances efficiency, reduces human error, and minimizes the learning curve, making these machines accessible to a broader range of operators.With the impressive capabilities and features of [Company Name]'s fiber laser cutter machines, it comes as no surprise that they have received global recognition and trust. The company has established a solid reputation by delivering cutting-edge, reliable, and customized solutions that cater to various industry needs. By leveraging the power of fiber laser technology, they have successfully transformed metal cutting processes, enabling businesses to streamline their operations and maximize productivity.In conclusion, the advent of fiber laser cutter machines has revolutionized metal cutting processes by delivering unprecedented levels of speed, precision, and efficiency. [Company Name]'s commitment to innovation and customer satisfaction has propelled them to the forefront of this technological advancement. Their fiber laser cutter machines are a testament to their expertise and dedication in providing reliable, high-quality solutions that meet the evolving needs of the industrial sector.

Wood Carving Machine: A Powerful Tool for Precision and Efficiency

Title: Revolutionary Machine for Wood Carving Revolutionizes the CraftIntroduction:Wood carving has long been considered a timeless art form, requiring immense skill, patience, and precision. However, with the introduction of a cutting-edge wood carving machine by an innovative company, artisans around the world can now embrace a new era of craftsmanship. This groundbreaking technology enables woodworkers to achieve unprecedented levels of intricacy and detail in their creations, transforming their visions into reality like never before.Enhancing Precision and Efficiency in Wood Carving:Traditional wood carving techniques often relied on manual tools, resulting in hours, if not days, of labor-intensive work. However, with the advent of this advanced machine, the processes have been drastically expedited, while maintaining the same high standards of artistry.This state-of-the-art wood carving machine removes human error by utilizing computer numerical control (CNC) technology. It employs a range of cutting, shaping, and engraving tools to sculpt wood with remarkable accuracy and precision. This not only saves time and effort but also minimizes wastage, making it an environmentally friendly option for wood craftsmen.Intuitive Design Software for Customization:Accompanying this innovative machine is an intuitive design software, allowing artists to bring their creative ideas to life effortlessly. With a user-friendly interface, woodworkers can easily translate their unique designs into digital models, which are then replicated by the machine with impeccable precision.The software offers a variety of design templates and allows for customization, ensuring that no limitation is imposed on the artist's vision. This flexibility empowers artisans to experiment with intricate patterns, textures, and depths, creating truly distinctive pieces that captivate the viewer's imagination.Expanding Creativity with a Wide Range of Applications:The wood carving machine's capabilities extend beyond traditional carving techniques. It opens up a world of possibilities for artists, allowing them to explore new dimensions in woodworking.From crafting intricate furniture pieces and decorative accents to designing personalized sculptures and architectural elements, this machine offers endless potential for woodworkers to push the boundaries of their creativity. Additionally, the precision and consistency offered by the machine make it suitable for mass production, revolutionizing the woodworking industry.Unleashing Opportunities for Artisans:The introduction of this cutting-edge wood carving machine not only transforms the art of woodworking but also presents lucrative opportunities for skilled artisans. By harnessing the power of technology, woodworkers can streamline their production process, meet increasing demands, and reach a larger audience.The machine's capability to deliver meticulous results consistently allows woodworkers to undertake more complex and elaborate projects. This, in turn, enhances their reputation and opens doors to collaborations with interior designers, architects, and even the film industry. The machine offers a competitive edge to artisans, enabling them to establish themselves as industry leaders in the realm of wood carving.Environmentally Friendly and Sustainable:Beyond its technical prowess, the wood carving machine is designed with sustainability at its core. It utilizes responsibly sourced wood and minimizes waste by optimizing material usage. The CNC technology employed by the machine ensures efficient cutting and shaping, reducing the environmental footprint associated with traditional wood carving methods.By integrating this machine into their workflow, woodworkers are contributing to a more sustainable future for the craft, aligning themselves with the growing eco-conscious consumer base.Conclusion:The introduction of this revolutionary wood carving machine has elevated the art form to new heights, blending traditional craftsmanship with state-of-the-art technology. Woodworkers can now unleash their creativity and push the boundaries of their craft with unparalleled precision and efficiency. Moreover, this advancement opens up opportunities for artisans to reach new markets and collaborate with various industries, securing a prosperous future for the art of wood carving.