High-quality 12x12 CNC Router: A Game-changer in Precision Woodworking

By:Admin

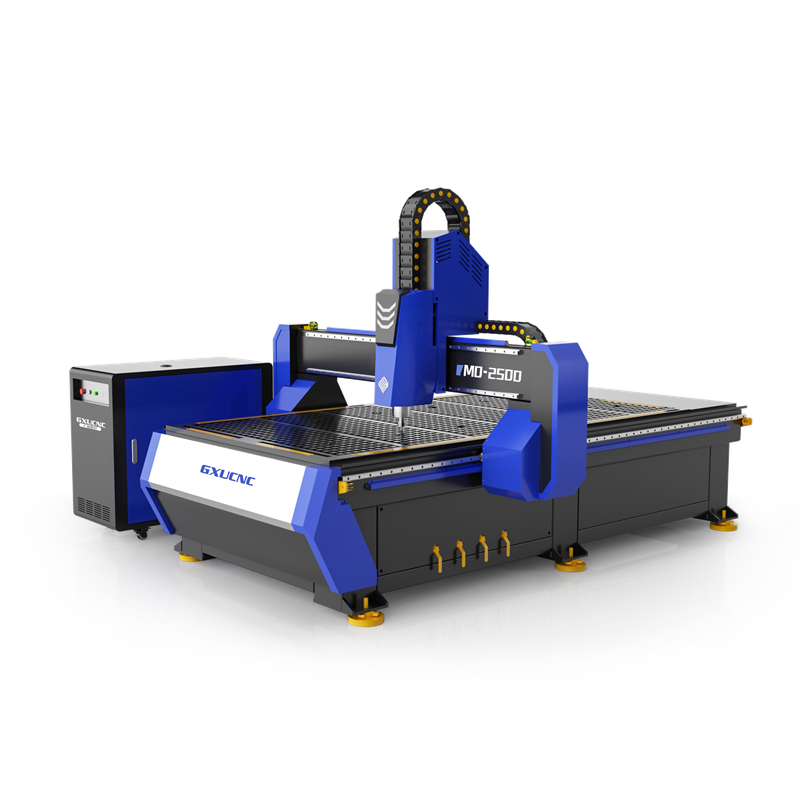

The 12x12 CNC router is a versatile machine that is designed for precision cutting and carving of various materials such as wood, plastic, and foam. Its robust construction and high-quality components ensure that it can handle even the most demanding tasks with ease. With a cutting area of 12x12 inches, this machine offers ample space for creating intricate designs and detailed patterns.

One of the key features of the 12x12 CNC router is its high-speed spindle, which is capable of reaching speeds of up to 24,000 RPM. This ensures smooth and efficient cutting, resulting in high-quality finishes and reduced production times. Additionally, the machine is equipped with a state-of-the-art control system that allows for easy programming and operation, making it suitable for both beginners and experienced users.

In addition to its cutting and carving capabilities, the 12x12 CNC router also offers a range of other features that make it an ideal choice for a wide range of applications. Its compatibility with various CAD/CAM software allows for seamless integration with existing workflows, while its sturdy construction and reliable performance make it suitable for both professional and hobbyist users.

The launch of the 12x12 CNC router is a testament to [Company Name]'s commitment to innovation and excellence in the field of CNC machining. With a long-standing reputation for producing high-quality machines, the company continues to push the boundaries of what is possible in the industry. This latest offering further cements their position as a leader in the market, with a focus on delivering cutting-edge solutions to their customers.

"We are thrilled to introduce the 12x12 CNC router to the market," said [Spokesperson Name], [Title] at [Company Name]. "This machine represents the culmination of years of research and development, and we believe it will have a significant impact on the industry. We are confident that it will meet the needs of our customers and provide them with a reliable and efficient solution for their CNC machining requirements."

The 12x12 CNC router is now available for purchase through [Company Name]'s network of authorized distributors and dealers. With its user-friendly design, versatile capabilities, and robust construction, it is expected to be a popular choice among those seeking a high-performance CNC machine for their workshops or production facilities.

For more information about the 12x12 CNC router and other products offered by [Company Name], visit their website or contact their sales team directly. With a commitment to customer satisfaction and a track record of delivering top-quality machines, [Company Name] continues to be a trusted name in the CNC machining industry.

Company News & Blog

Powerful Laser Rust Remover – A Must-Have Tool for Rust Removal

Laser Rust Removal, the Innovative Solution for Rust ProblemsRust is a common problem that many individuals and industries face. Whether it's on automotive parts, machinery, or infrastructure, rust can cause serious damage and deterioration if not addressed properly. Traditional rust removal methods such as sandblasting and chemical treatments can be time-consuming, labor-intensive, and potentially harmful to the environment. Fortunately, there is now a cutting-edge solution that is revolutionizing the way rust is removed – laser rust removal.Theis technology utilizes high-powered lasers to effectively and efficiently remove rust from metal surfaces. The laser energy is absorbed by the rust, causing it to heat up and evaporate, leaving behind a clean and rust-free surface. This process is not only incredibly precise, but it also eliminates the need for harsh chemicals and reduces the amount of waste produced during the rust removal process.One company that is leading the way in laser rust removal technology is the innovative company. With a commitment to providing sustainable and environmentally friendly solutions, they have developed a range of laser rust removal machines that are suitable for a variety of applications. Their machines are compact, portable, and easy to use, making them ideal for use in workshops, manufacturing plants, and even on-site maintenance and repair jobs.The company's laser rust removal machines are designed to be user-friendly, with intuitive controls and safety features to ensure that operators can use them with confidence and peace of mind. In addition to their standard machines, they also offer custom solutions for clients with specific rust removal needs, demonstrating their commitment to meeting the unique requirements of their customers.The effectiveness of the company's laser rust removal machines has been demonstrated in a wide range of industries, including automotive, aerospace, marine, and manufacturing. Not only does this technology remove rust quickly and efficiently, but it also does so without causing damage to the underlying metal, resulting in a surface that is ready for painting, coating, or further treatment.One of the key advantages of laser rust removal is its ability to reach areas that are difficult to access with traditional rust removal methods. This includes intricate and complex shapes, tight corners, and areas with a high degree of detail. With the ability to precisely target and remove rust from these hard-to-reach areas, the company's laser rust removal machines are a versatile and valuable tool for any industry dealing with rust issues.In addition to its practical benefits, laser rust removal also offers significant cost savings in the long run. By reducing the need for manual labor and minimizing the use of chemicals and abrasive materials, companies can lower their operational costs and improve their overall efficiency. Furthermore, the environmental benefits of laser rust removal cannot be overstated, as it eliminates the release of harmful substances into the environment, making it a truly sustainable rust removal solution.With the increasing demand for environmentally friendly and efficient rust removal solutions, the company's laser rust removal machines are quickly becoming a preferred choice for businesses looking to maintain their equipment and infrastructure. As the industry continues to evolve, the company remains at the forefront of innovation, continuously improving its technology and expanding its product line to meet the diverse needs of its customers.In conclusion, laser rust removal is a game-changing technology that is revolutionizing the way rust is removed from metal surfaces. With its precision, efficiency, and environmental benefits, it has become the go-to solution for industries looking to combat rust and preserve the integrity of their equipment and assets. The company is at the forefront of this innovative technology, offering a range of laser rust removal machines that are setting new standards for rust removal efficiency and sustainability. As the demand for sustainable rust removal solutions continues to grow, the company is poised to lead the way in providing cutting-edge solutions for industries around the world.

Top Vacuum Table for Cnc Router: Ultimate Guide

CNC Router Vacuum Table Revolutionizes Woodworking IndustryIn the fast-paced world of woodworking, efficiency and precision are key. That's why the introduction of the new CNC Router Vacuum Table from a leading woodworking machinery manufacturer has caused a ripple of excitement throughout the industry. This innovative product is set to revolutionize the way woodworkers approach their craft, offering a level of precision and ease of use that was previously unheard of.The CNC Router Vacuum Table is designed to securely hold workpieces in place during the milling or machining process. This is achieved using a powerful vacuum system that creates a strong hold on the workpiece, preventing any movement or slippage during the cutting process. This level of security not only reduces the risk of errors or damage to the workpiece, but also allows for more complex and detailed designs to be executed with ease.One of the standout features of the CNC Router Vacuum Table is its versatility. With a range of sizes and configurations available, this product is suitable for a wide variety of woodworking applications. Whether it's a small-scale hobbyist project or a large-scale industrial operation, the CNC Router Vacuum Table can be customized to fit the specific needs of the user.In addition to its secure hold and versatility, the CNC Router Vacuum Table also boasts a user-friendly design that makes it a breeze to operate. With intuitive controls and a straightforward setup process, woodworkers of all skill levels can quickly get to grips with this innovative piece of machinery.The introduction of the CNC Router Vacuum Table is a testament to the company's dedication to staying at the forefront of technological innovation in the woodworking industry. With a strong focus on research and development, as well as a commitment to providing high-quality products and exceptional customer service, the company has become a trusted name in the world of woodworking machinery.Incorporating cutting-edge technology and a deep understanding of the needs of woodworkers, the CNC Router Vacuum Table is just one example of the company's ongoing efforts to push the boundaries of what is possible in the field of woodworking. By consistently delivering products that exceed expectations and raise the bar for quality and performance, the company has solidified its position as a leader in the industry.The introduction of the CNC Router Vacuum Table has been met with widespread enthusiasm from woodworkers, with many expressing excitement about the potential for improved efficiency and precision in their work. With its ability to securely hold workpieces, its versatility, and its user-friendly design, this innovative product is set to have a significant impact on the woodworking industry as a whole.As the company continues to push the boundaries of what is possible in woodworking machinery, it is clear that the introduction of the CNC Router Vacuum Table is just the beginning. With a strong track record of innovation and a commitment to excellence, the company is poised to continue leading the industry into the future.In conclusion, the introduction of the CNC Router Vacuum Table represents a major milestone in the world of woodworking machinery. With its powerful vacuum system, versatility, and user-friendly design, this innovative product is set to revolutionize the way woodworkers approach their craft. As the company continues to innovate and push the boundaries of what is possible in woodworking, the future looks bright for woodworkers everywhere.

Efficient Fiber Cutting Machine Revolutionizes Industrial Cutting Processes

Title: Revolutionary Fiber Cutting Machine Revolutionizes Manufacturing ProcessesIntroduction:In an era dominated by technological advancements, the manufacturing industry has witnessed remarkable progress in the form of the revolutionary Fiber Cutting Machine. This cutting-edge technology, developed by a renowned company that specializes in cutting solutions, promises to transform manufacturing processes across various industries. This game-changing innovation is set to enhance productivity, accuracy, and efficiency, leading to significant cost savings and improved product quality. In this article, we delve into the features, benefits, and potential applications of this groundbreaking Fiber Cutting Machine, which is poised to become an industry standard in the near future.Section 1: Background InformationThe Fiber Cutting Machine, developed by [Company Name], stands at the forefront of precision cutting advancements. Equipped with state-of-the-art technology and cutting-edge components, this machine has been designed to cater to the diverse needs of manufacturers across different sectors.Section 2: Features and FunctionalityThe [Company Name]'s Fiber Cutting Machine boasts several innovative features that set it apart from traditional cutting methods. Firstly, it utilizes advanced fiber optics, ensuring impeccable precision and accuracy. With integrated sensors and a powerful computerized system, the machine delivers consistent results, eliminating human error and reducing waste. Additionally, the machine's intelligent software allows for seamless customization, enabling manufacturers to easily adapt to the ever-evolving demands of their clients.Section 3: Benefits and AdvantagesThe adoption of the Fiber Cutting Machine offers a multitude of advantages for manufacturing facilities. Firstly, this technology significantly reduces production time, leading to increased productivity and faster turnaround times. The machine's quick setup and automated operations streamline the manufacturing process, reducing the overall time and effort required to produce high-quality components.Moreover, the accuracy and precision offered by the Fiber Cutting Machine guarantee a higher level of consistency and quality in the final products. This improvement helps manufacturers maintain a competitive edge in the market while minimizing rejection rates and costly rework. By reducing material wastage, the machine also contributes to more sustainable and environmentally friendly manufacturing practices.Section 4: Applications and IndustriesThe versatility of the [Company Name]'s Fiber Cutting Machine allows it to cater to a wide range of industries. Whether it is automotive, aerospace, electronics, or even medical devices, the machine provides the necessary precision to fabricate intricate components. In the automotive sector, for instance, the Fiber Cutting Machine is used to manufacture lightweight yet sturdy vehicle parts, contributing to enhanced fuel efficiency and reduced emissions.In the aerospace industry, the machine plays a crucial role in creating durable and lightweight components that withstand extreme conditions. The electronics sector benefits from the Fiber Cutting Machine's ability to produce miniaturized components with exceptional precision, enabling the creation of technologically advanced devices. Additionally, the machine's sterile cutting environment makes it ideal for manufacturing medical devices, ensuring uncompromised quality and safety.Section 5: Future OutlookAs manufacturers increasingly prioritize efficiency and precision, the Fiber Cutting Machine is poised to become an integral part of their operations. With its numerous advantages and versatility, this cutting-edge technology has the potential to revolutionize the manufacturing landscape in the coming years. The [Company Name] aims to constantly innovate and refine their Fiber Cutting Machine, further expanding its capabilities to match the evolving industry requirements.Conclusion:The Fiber Cutting Machine developed by [Company Name] presents a paradigm shift in the manufacturing industry. Through its advanced features, unmatched precision, and numerous benefits, this cutting-edge technology empowers manufacturers to achieve new heights of efficiency, accuracy, and cost-effectiveness. As the industry embraces this revolutionary machine, we can anticipate a transformative impact on manufacturing processes, ultimately contributing to a brighter and more technologically advanced future.

Cutting Edge 3D Wood CNC Machine for Precision Woodworking

Introducing Innovative 3D Wood Cutting CNC Machine Revolutionizing the IndustryWoodworking has been an essential craft for centuries, and with the advancement of technology, the industry has witnessed significant improvements. [Company Name], an innovative leader in manufacturing machinery, is now introducing an extraordinary 3D Wood Cutting CNC Machine that is set to revolutionize the woodworking industry. This cutting-edge machine promises exceptional precision, efficiency, and versatility, making it a must-have tool for woodworkers of all levels.The 3D Wood Cutting CNC Machine is a state-of-the-art device that combines the latest advancements in computer numerical control (CNC) technology with woodcutting capabilities. This machine allows woodworkers to create intricate designs and shapes on various wood types with unparalleled precision and speed. Whether it’s crafting detailed furniture, ornate decorations, or personalized signage, this machine opens up a world of possibilities for woodworkers.The main highlight of this machine is its ability to offer three-dimensional cutting capabilities, revolutionizing the traditional two-dimensional woodcutting process. With this new feature, woodworkers can transform their projects into stunning three-dimensional works of art. The precision and intricate detailing enabled by this machine are unparalleled, ensuring a flawless finish every time.Another outstanding feature of this CNC machine is its user-friendly interface and easy setup process. Advanced software integrated into the machine allows users to design their projects digitally before executing them with precision. This software provides tools for customizing designs, adjusting dimensions, and even importing designs from external sources. With just a few clicks, users can transform their ideas into digital realities and bring them to life through woodcutting.Efficiency is a crucial aspect of any woodworking project, and this machine addresses that need perfectly. The 3D Wood Cutting CNC Machine is designed to minimize material waste, ensuring optimal utilization and cost-effectiveness. Its precise cutting mechanism ensures that every piece of wood is utilized effectively, reducing both time and the requirement for additional materials. This efficiency provides woodworkers with a competitive edge, enabling them to take on more projects and deliver them in shorter time frames.Furthermore, this CNC machine offers a wide range of compatibility with various wood types, including softwoods, hardwoods, and engineered woods. It can seamlessly cut through thick and thin wood sheets, maintaining the same level of precision throughout. This versatility eliminates the need for different machines for different materials, making it an ideal investment for woodworking businesses looking to streamline their operations.In addition to its extraordinary features, [Company Name] provides exceptional after-sales support and training to customers. Their team of experts offers comprehensive training on operating the machine, utilizing the digital design software, and troubleshooting common issues. This ensures that woodworkers can maximize the machine's potential and overcome any challenges they may face along the way.With its innovative design, precision, versatility, and efficiency, the 3D Wood Cutting CNC Machine from [Company Name] is set to redefine the woodworking industry. Whether you are a seasoned professional or an amateur woodworker, this machine is a game-changer that enables you to explore your creativity and bring your designs to life. Invest in this cutting-edge technology to enhance your woodworking capabilities and take your projects to new heights.

Advanced Laser Technology for Derusting: A Complete Guide

Introducing the Future of Derusting Technology: Derusting LaserIn the fast-paced world of industrial innovation, companies are constantly seeking advanced solutions to improve efficiency and productivity. One such innovation that has been making waves in the industrial sector is the Derusting Laser, a cutting-edge technology that is revolutionizing the derusting process.Traditional methods of derusting, such as sandblasting and chemical treatments, are not only time-consuming but also pose environmental and health risks. In contrast, the Derusting Laser offers a safe, efficient, and environmentally friendly alternative that is quickly gaining traction in various industries.Developed by a leading manufacturer of industrial laser equipment, the Derusting Laser utilizes the power of high-intensity laser beams to remove rust and corrosion from metal surfaces. The precise and controlled nature of the laser technology allows for targeted derusting without causing damage to the underlying metal, resulting in a superior finish and prolonged durability.This innovative technology is particularly well-suited for industries such as automotive, manufacturing, aerospace, and maritime, where the maintenance of metal equipment and structures is essential. By eliminating the need for harsh chemicals and abrasive techniques, the Derusting Laser not only streamlines the derusting process but also reduces operational costs and environmental impact.In addition to its superior derusting capabilities, the Derusting Laser is also designed with user-friendly features that enhance its practicality and versatility. With customizable settings and automated controls, operators can effortlessly adapt the laser technology to various derusting applications, saving time and labor while ensuring consistent and high-quality results.Furthermore, the manufacturer of the Derusting Laser is committed to providing comprehensive support and training to ensure seamless integration and optimal performance. This includes ongoing technical assistance, maintenance services, and educational resources to empower clients with the knowledge and skills to maximize the potential of the technology.As the demand for sustainable and efficient derusting solutions continues to grow, the Derusting Laser is poised to become the go-to choice for industrial operators seeking to enhance their maintenance practices. By embracing this cutting-edge technology, companies can not only achieve superior derusting results but also contribute to a safer and greener working environment.With its remarkable capabilities and the backing of a reputable manufacturer, the Derusting Laser is set to redefine the standards of derusting technology and lead the way towards a more advanced and sustainable industrial future.In conclusion, the Derusting Laser presents a compelling solution for the challenges of derusting in modern industries. With its advanced technology, user-friendly features, and comprehensive support, it is poised to make a significant impact on the way metal surfaces are maintained and preserved. As industries continue to prioritize efficiency, sustainability, and safety, the Derusting Laser is well-positioned to become an indispensable tool for the future of derusting technology.

Highly Efficient Benchtop Laser Welder for Precise Welding Operations

In the world of manufacturing and engineering, precision and efficiency are key components to success. This is where the Benchtop Laser Welder comes into play. This advanced technology has revolutionized the way that companies can weld and join materials, providing a level of accuracy and speed that was previously unattainable. With its compact design and powerful capabilities, the Benchtop Laser Welder has quickly become a go-to solution for many industries, including automotive, aerospace, and electronics.The Benchtop Laser Welder, developed by a leading global company in laser technology, is a game-changer for businesses looking to improve their welding processes. The company, known for its innovative and cutting-edge solutions, has been at the forefront of laser technology for decades. With a focus on research and development, they have continuously pushed the boundaries of what is possible with laser technology, and the Benchtop Laser Welder is a shining example of their commitment to excellence.One of the key features of the Benchtop Laser Welder is its versatility. It is capable of welding a wide range of materials, including metals, plastics, ceramics, and more. This versatility makes it an invaluable tool for companies that work with diverse materials, as they can rely on the Benchtop Laser Welder to handle all of their welding needs. Additionally, its precision and accuracy ensure that welds are strong and durable, meeting the high standards required in industries such as automotive and aerospace.Another standout feature of the Benchtop Laser Welder is its speed. Traditional welding methods can be time-consuming and labor-intensive, but the Benchtop Laser Welder streamlines the process, allowing for faster production times and increased output. This is crucial for companies looking to stay competitive in today's fast-paced market, where efficiency is paramount.Furthermore, the Benchtop Laser Welder is designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels, reducing the need for extensive training or specialized expertise. This, in turn, can lead to cost savings for businesses, as they can utilize existing personnel to operate the Benchtop Laser Welder without the need for additional training or hiring specialized technicians.The compact design of the Benchtop Laser Welder is also a significant advantage. Traditional welding equipment often takes up a large amount of space, but the Benchtop Laser Welder's small footprint makes it an ideal solution for companies with limited floor space or those looking to maximize the use of their existing workspace. Additionally, its portability allows for easy repositioning within a facility, providing flexibility for changing production needs.The company behind the Benchtop Laser Welder is committed to providing exceptional customer support and service. From initial consultation to installation and ongoing maintenance, they work closely with their clients to ensure that the Benchtop Laser Welder meets their specific needs and delivers the expected results. This dedication to customer satisfaction has earned the company a reputation for excellence in the industry, solidifying its position as a trusted partner for businesses looking to invest in advanced welding technology.In conclusion, the Benchtop Laser Welder, developed by a leading company in laser technology, is a game-changing solution for businesses looking to improve their welding processes. With its versatility, speed, user-friendliness, and compact design, the Benchtop Laser Welder is redefining the standards for precision and efficiency in welding. As companies continue to seek innovative ways to stay competitive in today's market, the Benchtop Laser Welder is poised to play a pivotal role in driving their success.

Revolutionary Laser Technology for Removing Rust and Paint

The use of lasers in various industries has become increasingly common as technology advances. One company at the forefront of this movement is (need remove brand name), a leading developer of industrial laser solutions. One of their latest innovations is the Rust and Paint Removing Laser, a high-tech tool designed to efficiently and effectively remove unwanted coatings from a variety of surfaces.The Rust and Paint Removing Laser is a revolutionary new product that has the potential to drastically change the way rust and paint removal is carried out in industries such as automotive, aerospace, manufacturing, and construction. Traditional methods of rust and paint removal often involve manual labor, abrasive blasting, or chemical treatments, which can be time-consuming, labor-intensive, and potentially harmful to the environment. The Rust and Paint Removing Laser offers a safer, more efficient, and more environmentally friendly alternative.The technology behind the Rust and Paint Removing Laser is based on precision laser ablation, which effectively removes rust, paint, and other coatings from metal, concrete, and other surfaces without damaging the underlying material. This makes it an ideal solution for industries that require precise and delicate surface treatment, such as the aerospace industry, where the integrity of the underlying material is extremely important.The (need remove brand name) Rust and Paint Removing Laser is also highly versatile, with the ability to adjust laser parameters to suit different materials and coating types. This flexibility allows for a wide range of applications, from small-scale projects to large-scale industrial operations. Additionally, the laser system is designed to be user-friendly, with intuitive controls and a straightforward interface, making it accessible to operators with varying levels of experience.In addition to its practical benefits, the Rust and Paint Removing Laser also offers significant cost savings for businesses. By eliminating the need for costly and potentially hazardous chemical treatments, as well as reducing the time and labor required for manual coating removal, the laser system can help companies streamline their operations and improve their bottom line.Furthermore, the Rust and Paint Removing Laser aligns with (need remove brand name)'s commitment to sustainability. By offering a more environmentally friendly alternative to traditional coating removal methods, the company is contributing to the long-term health of the planet and promoting responsible industrial practices.The development of the Rust and Paint Removing Laser is just one example of how (need remove brand name) is pushing the boundaries of what is possible with industrial laser technology. The company has a long history of innovation and a track record of delivering cutting-edge solutions to its customers. Their team of experienced engineers and technicians are dedicated to staying at the forefront of technological advancements and providing their clients with the most advanced and effective laser solutions.In addition to their Rust and Paint Removing Laser, (need remove brand name) offers a range of other industrial laser solutions, including laser cutting, welding, marking, and engraving systems. These products are used in a wide variety of industries, including automotive, electronics, medical devices, and more, and are known for their reliability, precision, and efficiency.As the demand for advanced laser technology continues to grow, (need remove brand name) is well-positioned to lead the way in developing new and innovative solutions for the industrial sector. Their commitment to quality, innovation, and sustainability sets them apart as a leader in the field of industrial laser technology. With the introduction of the Rust and Paint Removing Laser, (need remove brand name) has once again demonstrated their ability to meet the evolving needs of their customers and provide real value to the industries they serve.

High-Powered 2000w Laser Welding Machine: The Latest in Welding Technology

Laser Welding Machine 2000wLaser technology has become an integral part of various industrial processes, and laser welding is one of the most advanced and efficient methods for joining metals. The Laser Welding Machine 2000w, developed by a leading company in the industry, has become a game-changer in the field of metal fabrication and manufacturing.The Laser Welding Machine 2000w is equipped with state-of-the-art technology that allows for precise and high-speed welding of various metals, including steel, aluminum, and titanium. This high-powered machine can tackle complex welding tasks with ease, making it a valuable asset for any industrial setting.One of the key features of the Laser Welding Machine 2000w is its advanced control system, which enables operators to adjust the welding parameters with pinpoint accuracy. This level of control ensures that the welding process is optimized for each specific application, resulting in high-quality and consistent welds.In addition, the machine is designed for versatility, with the ability to handle both spot welding and seam welding tasks. This makes it a highly flexible solution for a wide range of production requirements, from small-scale operations to large-scale manufacturing facilities.The company behind the Laser Welding Machine 2000w has a strong track record in delivering cutting-edge laser technology solutions to the industry. With a focus on innovation and customer satisfaction, the company has built a reputation for excellence in providing high-quality and reliable equipment.Furthermore, the company offers comprehensive support and training for the Laser Welding Machine 2000w, ensuring that customers are able to maximize the full potential of the equipment. This includes assistance with installation, operator training, and ongoing technical support to address any maintenance or operational needs.The Laser Welding Machine 2000w has already made a significant impact in various industries, including automotive, aerospace, and electronics manufacturing. Its ability to deliver superior welding performance with efficiency and precision has garnered praise from customers and industry experts alike.One key customer, a leading automotive manufacturer, has reported substantial improvements in their production processes since implementing the Laser Welding Machine 2000w. The machine has enabled them to achieve higher welding speeds and improved weld quality, resulting in overall cost savings and enhanced product quality.In conclusion, the Laser Welding Machine 2000w represents a leap forward in laser welding technology, offering advanced capabilities and exceptional performance for the most demanding industrial applications. Backed by a reputable company with a commitment to excellence, this machine is poised to continue making a significant impact in the manufacturing and fabrication sector. As industries continue to evolve and demand higher levels of precision and efficiency, the Laser Welding Machine 2000w is well-positioned to meet and exceed these expectations.

Explore the Latest CNC Milling Machine - Revolutionizing Small-Scale Machining

Title: Innovation in Precision Manufacturing with Advanced Mini CNC Milling MachinesIntroduction:In today's fast-paced world, precision manufacturing plays a pivotal role in various industries, from aerospace and automotive to electronics and medical equipment. With the ever-increasing demand for intricately designed and flawlessly executed components, companies are constantly seeking innovative tools that offer enhanced precision and efficiency. One such ground-breaking solution is the cutting-edge mini CNC milling machine, produced by a renowned industry-leading company. This article delves into the features, benefits, and the impact of this state-of-the-art equipment in revolutionizing precision manufacturing processes.Feature Highlights:The mini CNC milling machine developed by the company harnesses cutting-edge technology to deliver exceptional precision and versatility. Equipped with advanced computer numerical control (CNC), this machine allows for automated control and precise three-dimensional (3D) milling operations. The compact design enables it to fit seamlessly into various manufacturing environments, including small workshops and research labs.Enhanced Accuracy:Designed with meticulous attention to detail, the mini CNC milling machine offers unparalleled accuracy in the manufacturing process. The integration of innovative servo control systems ensures precise movement of the spindle and worktable, resulting in superior finished products with minimal errors or rework. This level of precision opens new avenues for manufacturers who strive for excellence in their craftsmanship.Versatility in Material Machining:The versatility of the mini CNC milling machine is a game-changer in precision manufacturing. Its robust structure allows for the machining of various materials, including metals, plastics, and composites. This adaptability enables companies to streamline production processes by consolidating multiple machining tasks into a single machine. With the ability to handle a wide range of materials, businesses can save time, reduce costs, and enhance overall efficiency.User-Friendly Interface:Understanding the importance of user experience, the company has developed an ergonomic and intuitive interface for the mini CNC milling machine, ensuring ease of operation for personnel at any skill level. The user-friendly control panel offers extensive functionalities, such as tool path visualization, parameter adjustments, and real-time monitoring, empowering operators to optimize operations and maintain productivity. Additionally, the machine's compatibility with various design software allows seamless integration into existing manufacturing workflows.Improved Production Speed:The mini CNC milling machine's state-of-the-art technology enables faster production cycles without compromising precision. Utilizing high-speed spindles and advanced cutting tools, the machine increases throughput while maintaining excellent surface finish quality. Manufacturers can meet tighter deadlines and cater to customer demands more efficiently, granting them a competitive edge in the market.Revolutionizing Precision Manufacturing:The introduction of the mini CNC milling machine has transformed the landscape of precision manufacturing, offering numerous benefits across industries. For aerospace manufacturers, it enables the production of intricate components with perfect tolerances, contributing to safer and more efficient aircraft. Automotive companies can benefit from its streamlined workflows, resulting in higher-quality parts and improved vehicle performance. Further, the medical industry can leverage the precision of this machine to manufacture critical implants, prosthetics, and surgical instruments, ensuring better patient outcomes.Conclusion:The innovative mini CNC milling machine, developed by the renowned industry-leading company, has revolutionized precision manufacturing across diverse sectors. With its exceptional accuracy, material versatility, user-friendly interface, increased production speed, and numerous other cutting-edge features, this advanced machinery sets new standards in the industry. As demands for superior quality and efficiency continue to rise, the mini CNC milling machine stands as a testament to the pursuit of excellence through technological innovation.

Top 3D Wood Router for CNC Machining: A Comprehensive Guide

[Company name] is proud to announce the launch of its latest innovation, the CNC Wood Router 3D. This cutting-edge technology is set to revolutionize woodworking and bring a new level of precision and efficiency to the industry.The CNC Wood Router 3D is a powerful and versatile machine that is capable of cutting, engraving, and shaping wood with incredible precision. Its 3D capabilities allow for intricate and detailed designs to be brought to life, making it ideal for a wide range of applications including furniture production, cabinetry, sign making, and much more.One of the key features of the CNC Wood Router 3D is its advanced software that allows for easy and intuitive design and programming. This means that even those new to CNC technology can quickly learn and start producing high-quality work. The machine is also equipped with a high-speed spindle that ensures fast and efficient cutting, saving both time and labor costs for businesses."We are thrilled to introduce the CNC Wood Router 3D to the market," said [Company name] spokesperson. "We believe that this machine has the potential to transform the woodworking industry by bringing new levels of precision and efficiency. We have already received incredibly positive feedback from early users, and we are confident that this technology will be a game-changer for many businesses."The CNC Wood Router 3D is also designed with safety and durability in mind. Its strong and robust build ensures that it can handle heavy workloads and operate reliably for many years. The machine also features advanced safety mechanisms to protect users during operation, giving peace of mind to both operators and business owners.In addition to its technical capabilities, the CNC Wood Router 3D is also designed for ease of maintenance and service. This means that businesses can rely on the machine to consistently deliver high-quality results without the need for constant downtime and costly repairs.The launch of the CNC Wood Router 3D is a testament to [Company name]'s commitment to pushing the boundaries of innovation in the woodworking industry. With years of experience and expertise in CNC technology, the company has developed a reputation for delivering cutting-edge solutions that meet the needs of modern businesses.In addition to the CNC Wood Router 3D, [Company name] offers a wide range of CNC machines and accessories to cater to the diverse needs of the woodworking industry. Whether it's large-scale production or small-scale custom work, [Company name] has the technology and expertise to support businesses in achieving their goals.With the introduction of the CNC Wood Router 3D, [Company name] is poised to solidify its position as a leader in the woodworking industry. The company's dedication to excellence and innovation continues to drive its success, and the CNC Wood Router 3D is a prime example of how [Company name] is shaping the future of woodworking.Businesses interested in learning more about the CNC Wood Router 3D and [Company name]'s other offerings are encouraged to reach out to the company's sales team for more information. With personalized support and a commitment to delivering top-quality solutions, [Company name] is ready to help businesses take their woodworking operations to the next level.