Top 3D Wood Router for CNC Machining: A Comprehensive Guide

By:Admin

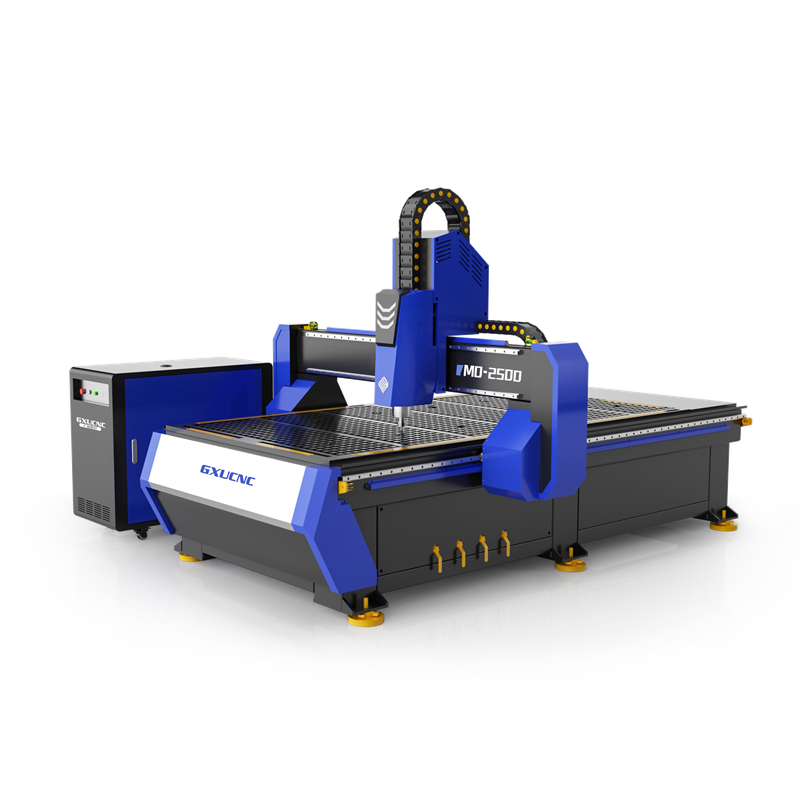

The CNC Wood Router 3D is a powerful and versatile machine that is capable of cutting, engraving, and shaping wood with incredible precision. Its 3D capabilities allow for intricate and detailed designs to be brought to life, making it ideal for a wide range of applications including furniture production, cabinetry, sign making, and much more.

One of the key features of the CNC Wood Router 3D is its advanced software that allows for easy and intuitive design and programming. This means that even those new to CNC technology can quickly learn and start producing high-quality work. The machine is also equipped with a high-speed spindle that ensures fast and efficient cutting, saving both time and labor costs for businesses.

"We are thrilled to introduce the CNC Wood Router 3D to the market," said [Company name] spokesperson. "We believe that this machine has the potential to transform the woodworking industry by bringing new levels of precision and efficiency. We have already received incredibly positive feedback from early users, and we are confident that this technology will be a game-changer for many businesses."

The CNC Wood Router 3D is also designed with safety and durability in mind. Its strong and robust build ensures that it can handle heavy workloads and operate reliably for many years. The machine also features advanced safety mechanisms to protect users during operation, giving peace of mind to both operators and business owners.

In addition to its technical capabilities, the CNC Wood Router 3D is also designed for ease of maintenance and service. This means that businesses can rely on the machine to consistently deliver high-quality results without the need for constant downtime and costly repairs.

The launch of the CNC Wood Router 3D is a testament to [Company name]'s commitment to pushing the boundaries of innovation in the woodworking industry. With years of experience and expertise in CNC technology, the company has developed a reputation for delivering cutting-edge solutions that meet the needs of modern businesses.

In addition to the CNC Wood Router 3D, [Company name] offers a wide range of CNC machines and accessories to cater to the diverse needs of the woodworking industry. Whether it's large-scale production or small-scale custom work, [Company name] has the technology and expertise to support businesses in achieving their goals.

With the introduction of the CNC Wood Router 3D, [Company name] is poised to solidify its position as a leader in the woodworking industry. The company's dedication to excellence and innovation continues to drive its success, and the CNC Wood Router 3D is a prime example of how [Company name] is shaping the future of woodworking.

Businesses interested in learning more about the CNC Wood Router 3D and [Company name]'s other offerings are encouraged to reach out to the company's sales team for more information. With personalized support and a commitment to delivering top-quality solutions, [Company name] is ready to help businesses take their woodworking operations to the next level.

Company News & Blog

Compact CNC Router: A Small-Scale Solution for Precision Cutting and Carving

Mini CNC Router: Revolutionizing Small-Scale ManufacturingIn the world of manufacturing, precision and efficiency are key factors for success. Large-scale industries have long benefited from the use of CNC (Computer Numerical Control) machines to automate their processes and achieve high levels of accuracy in their production. However, with the advancement of technology, the benefits of CNC machines are no longer limited to big industries. Small-scale businesses and hobbyists can now enjoy the same advantages with the introduction of mini CNC routers.One company at the forefront of this innovation is {}. With years of experience and expertise in the manufacturing industry, they have developed a mini CNC router that is set to revolutionize small-scale manufacturing. This new addition to their product line is designed to cater to the needs of small businesses, DIY enthusiasts, and educational institutions, offering a cost-effective solution for producing high-quality parts and prototypes.The mini CNC router offered by {} is equipped with the latest technology, including a high-speed spindle, precision linear guides, and a robust frame that ensures stability and accuracy during operation. Despite its compact size, this machine is capable of handling a wide range of materials such as wood, plastic, acrylic, and even non-ferrous metals, making it a versatile tool for various applications.One of the key features of this mini CNC router is its user-friendly interface, which allows operators to easily program and control the machine using intuitive software. This accessibility makes it an ideal choice for small businesses that may not have extensive experience with CNC technology. With a minimal learning curve, operators can quickly adapt to the machine and start producing intricate designs with ease.The mini CNC router also offers a significant advantage in terms of cost and space. Unlike traditional CNC machines, which often require a large and dedicated workspace, this compact router can fit into small workshops or even home garages. Its affordability and low operating costs make it a viable option for small businesses looking to enhance their production capabilities.Furthermore, the versatility of the mini CNC router makes it a valuable asset for educational institutions. With this machine, students can gain hands-on experience in CNC machining, allowing them to develop valuable skills that are highly sought after in the manufacturing industry. By providing access to this technology, {} is contributing to the development of the next generation of skilled professionals.The introduction of mini CNC routers is not only changing the landscape of small-scale manufacturing but also opening up new opportunities for entrepreneurs and hobbyists. With the ability to transform digital designs into precise physical objects, individuals can now bring their ideas to life with unprecedented accuracy and efficiency.In conclusion, the mini CNC router from {} represents a significant advancement in small-scale manufacturing. By combining cutting-edge technology with user-friendly design, this machine has the potential to empower small businesses and individuals to thrive in the competitive world of manufacturing. With its versatility, cost-effectiveness, and space-saving attributes, the mini CNC router is set to become a game-changer for anyone looking to elevate their production capabilities.

Top 10 CNC Routers for Plastic in 2021: Buyer's Guide and Reviews

[Company Name] Introduces New CNC Router for Plastic: Revolutionizing the Manufacturing Process[City, Date] - [Company Name] is proud to announce the launch of their latest innovation, a state-of-the-art CNC router designed specifically for plastic materials. This new addition to the company's product line is set to revolutionize the manufacturing process for countless industries, providing increased precision, efficiency, and versatility.The new CNC router is equipped with advanced technology and features, making it suitable for a wide range of plastic machining applications. It boasts high-speed cutting capabilities and exceptional accuracy, allowing for intricate and complex designs to be produced with ease. With its user-friendly interface and intuitive controls, the machine is also easy to operate, making it accessible to both seasoned professionals and newcomers to the industry.In addition to its cutting-edge technology, the CNC router is built to withstand the demands of industrial production. Its robust construction and durable components ensure long-term reliability and performance, making it a valuable asset for any manufacturing facility. The machine's versatility is further enhanced by its ability to work with various types of plastic materials, including acrylic, PVC, polycarbonate, and more, opening up a world of possibilities for manufacturers."We are thrilled to introduce our new CNC router for plastic, which represents a significant advancement in our product offerings," said [Spokesperson], [Title] at [Company Name]. "This machine is the result of extensive research and development, aimed at addressing the evolving needs of the manufacturing industry. We believe that it will have a transformative impact on how plastic components are produced, and we are excited to see the innovative ways in which our customers will utilize this new technology."The introduction of the CNC router for plastic underscores [Company Name]'s commitment to providing cutting-edge solutions for the manufacturing sector. With a solid track record of delivering high-quality machinery and equipment, the company has established itself as a trusted partner for businesses across various industries. By staying at the forefront of technological advancements and understanding the evolving needs of its customers, [Company Name] continues to drive innovation and progress in the manufacturing landscape.In light of the global shift towards sustainable and recyclable materials, the demand for precision-engineered plastic components has been on the rise. From automotive parts to electronic enclosures, from signage to architectural elements, the applications for plastic machining are vast and diverse. The new CNC router for plastic from [Company Name] is poised to meet this growing demand, offering a solution that combines efficiency, accuracy, and reliability.The introduction of this new technology comes at a time when manufacturers are seeking ways to optimize their production processes and stay ahead of the competition. With its potential to streamline operations and enhance the quality of output, the CNC router for plastic holds the promise of significant cost savings and productivity gains for businesses. By empowering manufacturers to achieve more with less, [Company Name] is contributing to the advancement of the industry as a whole.As the manufacturing landscape continues to evolve, the role of advanced machinery and technology in driving progress cannot be overstated. The new CNC router for plastic from [Company Name] represents a significant step forward in this journey, offering a glimpse into the future of plastic machining. With its precision, speed, and versatility, this innovative tool is set to redefine how plastic components are manufactured, setting new standards for quality and efficiency in the process.For businesses seeking to elevate their production capabilities and stay ahead in a competitive market, the CNC router for plastic from [Company Name] presents a compelling opportunity. With its proven reliability, advanced features, and broad applicability, this machine has the potential to transform the way manufacturers approach plastic machining. As the industry embraces this new technology, the possibilities for innovation and growth are endless.In conclusion, the introduction of the CNC router for plastic marks a significant milestone for [Company Name] and the manufacturing industry at large. With its advanced technology, robust construction, and broad capabilities, this machine is set to make a profound impact on how plastic components are produced. As businesses harness the power of this innovation to optimize their processes and achieve new levels of efficiency, the potential for growth and success is boundless. [Company Name] remains dedicated to driving progress in the manufacturing sector, and the launch of this new CNC router is a testament to that ongoing commitment.

Advanced Laser Cutting Machine in Turkey for Precision Cutting and Engraving

Turkey is making great strides in the manufacturing industry with the introduction of the latest laser cutting machine. This state-of-the-art technology is set to revolutionize the way materials are cut and shaped, bringing a new level of precision and efficiency to the production process.The laser cutting machine, developed by a leading Turkish company, offers a wide range of applications for various industries. From metal fabrication to automotive parts manufacturing, the machine is capable of cutting through a variety of materials with unparalleled accuracy and speed.This cutting-edge technology is a testament to Turkey's commitment to innovation and advancement in the manufacturing sector. The country has long been a hub for industrial production, and the introduction of this new machine is a testament to its continued growth and development.The laser cutting machine is set to have a significant impact on the manufacturing industry in Turkey, offering a competitive edge to companies looking to streamline their production processes. With its ability to cut through materials quickly and precisely, the machine will help reduce production times and increase efficiency, ultimately leading to cost savings for manufacturers.In addition to its efficiency, the laser cutting machine also offers a level of precision that is unmatched by traditional cutting methods. This will allow manufacturers to create intricate and complex designs with ease, opening up new possibilities for product development and customization.The company behind the development of this cutting-edge technology has a strong track record in the manufacturing industry. With years of experience and expertise in the field, they have established themselves as a leader in providing innovative solutions for industrial production.The introduction of the laser cutting machine is a testament to the company's commitment to pushing the boundaries of what is possible in the manufacturing industry. By constantly striving for technological innovation, they have solidified their position as a key player in the Turkish manufacturing sector and are poised to lead the way in the industry's future development.The machine is set to be a game-changer for manufacturers in Turkey and beyond, offering a level of precision and efficiency that is unparalleled in the industry. With its ability to cut through a wide range of materials and its advanced technology, the laser cutting machine is set to revolutionize the way products are manufactured, giving companies a competitive edge in the global market.The launch of the laser cutting machine is a clear indication of Turkey's commitment to remaining at the forefront of technological innovation in the manufacturing industry. With its focus on research and development, the country continues to invest in cutting-edge technology, ensuring that its manufacturing sector remains globally competitive and productive.As Turkey continues to make advancements in the manufacturing sector, the introduction of the laser cutting machine is a testament to the country's position as a key player in the global economy. With its commitment to innovation and progress, Turkey is well-positioned to lead the way in shaping the future of industrial production.

Cut Through Metal With Precision: Explore the Power of Fiber Laser Cutters

Fiber Laser Cutter for Metal Revolutionizing Industrial Cutting ProcessesIn recent years, technological advancements have transformed various industries, facilitating efficient, precise, and cost-effective solutions. In the field of metal cutting, the introduction of fiber laser cutter machines has revolutionized industrial processes, ushering in a new era of efficiency and productivity. These cutting-edge machines are now widely adopted by companies across the globe, including the renowned industry leader - [Company Name].[Company Name] is a pioneering force in the field of laser cutting technology, renowned for their cutting-edge solutions and unmatched quality. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted global provider of industrial laser cutting equipment.The utilization of fiber laser technology in metal cutting is a major breakthrough due to its high efficiency, precision, and versatility. Fiber lasers leverage a specially designed optical fiber that maximizes the laser beam quality, resulting in extremely accurate and consistent cutting performances. These lasers are capable of cutting various metals, including stainless steel, aluminum, copper, and brass, with exceptional precision and smooth edges, eliminating the need for additional finishing processes.One of the standout features of [Company Name]'s fiber laser cutter machines is their remarkable speed and efficiency. With an impressive cutting speed that surpasses traditional CO2 laser cutters by up to three times, these machines significantly reduce downtime, allowing companies to handle large production volumes with ease. Moreover, the fiber laser cutter machines maintain their high cutting speeds even when working with complex designs or thicker materials, ensuring uninterrupted workflow and enhanced productivity.In addition to speed, these machines offer exceptional precision and accuracy. The concentrated and intense laser beam from the fiber laser minimizes the heat-affected zone on the material, ensuring clean and high-quality cuts. The advanced control systems integrated into [Company Name]'s machines enable precise control over cutting parameters, making it possible to achieve intricate designs with utmost accuracy. This precision not only optimizes material usage but also minimizes waste, resulting in cost savings and increased profitability for businesses.Furthermore, the fiber laser cutter machines are more energy-efficient than their CO2 counterparts. Operating on significantly lower power consumption, these machines contribute to reduced carbon footprints, aligning with sustainable manufacturing practices. The decreased power consumption also translates to cost savings for businesses in the long run, making it a win-win situation for both the environment and the company's bottom line.[Company Name]'s fiber laser cutter machines also boast notable user-friendly features, allowing both experienced operators and novices to utilize the technology seamlessly. The machines are equipped with intuitive controls, enabling easy adjustments of cutting parameters, such as speed and power, to meet specific project requirements. The user-friendly interface enhances efficiency, reduces human error, and minimizes the learning curve, making these machines accessible to a broader range of operators.With the impressive capabilities and features of [Company Name]'s fiber laser cutter machines, it comes as no surprise that they have received global recognition and trust. The company has established a solid reputation by delivering cutting-edge, reliable, and customized solutions that cater to various industry needs. By leveraging the power of fiber laser technology, they have successfully transformed metal cutting processes, enabling businesses to streamline their operations and maximize productivity.In conclusion, the advent of fiber laser cutter machines has revolutionized metal cutting processes by delivering unprecedented levels of speed, precision, and efficiency. [Company Name]'s commitment to innovation and customer satisfaction has propelled them to the forefront of this technological advancement. Their fiber laser cutter machines are a testament to their expertise and dedication in providing reliable, high-quality solutions that meet the evolving needs of the industrial sector.

Wood Carving Machine: A Powerful Tool for Precision and Efficiency

Title: Revolutionary Machine for Wood Carving Revolutionizes the CraftIntroduction:Wood carving has long been considered a timeless art form, requiring immense skill, patience, and precision. However, with the introduction of a cutting-edge wood carving machine by an innovative company, artisans around the world can now embrace a new era of craftsmanship. This groundbreaking technology enables woodworkers to achieve unprecedented levels of intricacy and detail in their creations, transforming their visions into reality like never before.Enhancing Precision and Efficiency in Wood Carving:Traditional wood carving techniques often relied on manual tools, resulting in hours, if not days, of labor-intensive work. However, with the advent of this advanced machine, the processes have been drastically expedited, while maintaining the same high standards of artistry.This state-of-the-art wood carving machine removes human error by utilizing computer numerical control (CNC) technology. It employs a range of cutting, shaping, and engraving tools to sculpt wood with remarkable accuracy and precision. This not only saves time and effort but also minimizes wastage, making it an environmentally friendly option for wood craftsmen.Intuitive Design Software for Customization:Accompanying this innovative machine is an intuitive design software, allowing artists to bring their creative ideas to life effortlessly. With a user-friendly interface, woodworkers can easily translate their unique designs into digital models, which are then replicated by the machine with impeccable precision.The software offers a variety of design templates and allows for customization, ensuring that no limitation is imposed on the artist's vision. This flexibility empowers artisans to experiment with intricate patterns, textures, and depths, creating truly distinctive pieces that captivate the viewer's imagination.Expanding Creativity with a Wide Range of Applications:The wood carving machine's capabilities extend beyond traditional carving techniques. It opens up a world of possibilities for artists, allowing them to explore new dimensions in woodworking.From crafting intricate furniture pieces and decorative accents to designing personalized sculptures and architectural elements, this machine offers endless potential for woodworkers to push the boundaries of their creativity. Additionally, the precision and consistency offered by the machine make it suitable for mass production, revolutionizing the woodworking industry.Unleashing Opportunities for Artisans:The introduction of this cutting-edge wood carving machine not only transforms the art of woodworking but also presents lucrative opportunities for skilled artisans. By harnessing the power of technology, woodworkers can streamline their production process, meet increasing demands, and reach a larger audience.The machine's capability to deliver meticulous results consistently allows woodworkers to undertake more complex and elaborate projects. This, in turn, enhances their reputation and opens doors to collaborations with interior designers, architects, and even the film industry. The machine offers a competitive edge to artisans, enabling them to establish themselves as industry leaders in the realm of wood carving.Environmentally Friendly and Sustainable:Beyond its technical prowess, the wood carving machine is designed with sustainability at its core. It utilizes responsibly sourced wood and minimizes waste by optimizing material usage. The CNC technology employed by the machine ensures efficient cutting and shaping, reducing the environmental footprint associated with traditional wood carving methods.By integrating this machine into their workflow, woodworkers are contributing to a more sustainable future for the craft, aligning themselves with the growing eco-conscious consumer base.Conclusion:The introduction of this revolutionary wood carving machine has elevated the art form to new heights, blending traditional craftsmanship with state-of-the-art technology. Woodworkers can now unleash their creativity and push the boundaries of their craft with unparalleled precision and efficiency. Moreover, this advancement opens up opportunities for artisans to reach new markets and collaborate with various industries, securing a prosperous future for the art of wood carving.

Top 10 Routers for Metal: A Guide to the Best Options

Wireless technology has transformed the way we work and live, and in industries like manufacturing and construction, the need for reliable and robust wireless connectivity is essential. This is where the new Router For Metal from a leading wireless technology company comes into play.The Router For Metal is a game-changing device that is specifically designed for use in environments where traditional routers may struggle to provide a stable and fast wireless connection. With its ruggedized design and advanced technology, this router is able to provide seamless wireless connectivity in even the harshest industrial environments.One of the key features of the Router For Metal is its ability to withstand extreme temperatures and harsh weather conditions. This makes it an ideal choice for outdoor use in industries like construction, mining, and oil and gas, where traditional routers simply wouldn't be able to cope. Its durable metal housing provides protection against dust, water, and physical impact, ensuring that it can continue to operate reliably in even the toughest conditions.In addition to its rugged design, the Router For Metal also boasts advanced wireless technology that allows it to provide high-speed and reliable connectivity over long distances. This is essential in industries where machinery and equipment may be spread out over a large area, and a stable wireless connection is needed to ensure that everything operates smoothly and efficiently.Furthermore, the Router For Metal is equipped with the latest security features to protect against cyber threats and unauthorized access, providing peace of mind for businesses operating in sensitive and regulated industries.The company behind the Router For Metal has a long history of providing innovative wireless solutions for industrial and commercial applications. With a focus on reliability, performance, and durability, they have established themselves as a leader in the field of industrial wireless technology.Their team of expert engineers and designers are constantly pushing the boundaries of what is possible with wireless technology, developing products that meet the unique challenges and demands of industrial environments. The Router For Metal is the latest example of their commitment to providing cutting-edge solutions that empower businesses to operate more efficiently and effectively.The company's dedication to quality and customer satisfaction is evident in the Router For Metal, which has undergone rigorous testing and certification to ensure that it meets the highest standards for performance and reliability. This level of commitment to excellence is what sets them apart from other providers in the industry and has earned them the trust and loyalty of customers around the world.In addition to the Router For Metal, the company offers a range of other wireless products and solutions, including industrial-grade access points, antennas, and networking accessories. This comprehensive product line allows them to provide complete wireless connectivity solutions for a wide range of industrial and commercial applications, further cementing their reputation as a go-to provider for wireless technology in demanding environments.The launch of the Router For Metal represents a significant milestone for the company, as it demonstrates their ongoing dedication to innovation and their ability to provide tailored solutions for the unique needs of industrial customers. With its rugged design, advanced technology, and proven reliability, this router is set to become an essential tool for businesses operating in challenging industrial environments.As industries continue to embrace the benefits of wireless technology, the need for reliable and robust connectivity solutions will only continue to grow. With the Router For Metal, businesses can be confident that they have a trusted and proven solution that will enable them to operate at peak efficiency, no matter how demanding the environment.In conclusion, the Router For Metal from this leading wireless technology company represents a significant advancement in industrial wireless connectivity. Its rugged design, advanced technology, and proven reliability make it an ideal choice for businesses operating in challenging environments, and solidify the company's position as a top provider of industrial wireless solutions.

Top 3 Wood CNC Exporters for Quality 3 Axis Machines

3 Axis Wood Cnc Exporters is making waves in the woodworking industry as they continue to excel in the export market. Specializing in state-of-the-art CNC machines for wood processing, the company has gained a strong reputation for quality and reliability. With an extensive range of products and a commitment to innovation, they have positioned themselves as a leader in the global market.Established in [year], 3 Axis Wood Cnc Exporters has quickly grown to become a trusted name in the industry. Their dedication to providing top-quality CNC machines for wood processing has earned them a loyal customer base both domestically and internationally. With a focus on precision engineering and cutting-edge technology, the company has set itself apart as a frontrunner in the market.One of the key factors contributing to the success of 3 Axis Wood Cnc Exporters is their commitment to staying ahead of industry trends. By investing in research and development, the company has been able to continuously improve and expand their product offerings. This has allowed them to meet the ever-evolving needs of their customers and maintain a competitive edge in the market.In addition to their dedication to innovation, 3 Axis Wood Cnc Exporters places a strong emphasis on quality control. Each CNC machine undergoes rigorous testing to ensure that it meets the highest standards of performance and reliability. This attention to detail has resulted in a reputation for excellence and has helped the company build trust with their customers.Furthermore, 3 Axis Wood Cnc Exporters has been proactive in developing strong partnerships with international clients. By focusing on export opportunities, the company has been able to expand their reach and establish a global presence. This has not only allowed them to increase their market share but has also created new avenues for growth and development.The company's dedication to customer satisfaction is also a driving force behind their success. With a team of knowledgeable and responsive staff, 3 Axis Wood Cnc Exporters is committed to providing exceptional service to their clients. Whether it's answering technical questions, providing support, or assisting with product selection, the company goes above and beyond to ensure that their customers' needs are met.Looking ahead, 3 Axis Wood Cnc Exporters is poised for continued success in the global market. With a solid foundation built on innovation, quality, and customer service, the company is well-equipped to meet the challenges of an ever-changing industry. Their forward-thinking approach and unwavering commitment to excellence will undoubtedly propel them to even greater heights in the years to come.In conclusion, 3 Axis Wood Cnc Exporters has solidified its position as a leading exporter of CNC machines for wood processing. By prioritizing innovation, quality, and customer satisfaction, the company has carved out a strong presence in the global market. With a bright future ahead, 3 Axis Wood Cnc Exporters is set to continue making a significant impact in the woodworking industry.

Top CNC Wood Machinery for Efficient Woodworking Projects

CNC Wood, a leading provider of advanced woodworking machinery and equipment, has recently introduced a new range of innovative CNC wood cutting machines that are set to revolutionize the woodworking industry. The company, which has been at the forefront of technological advancements in the field of woodworking, continues to push the boundaries of what is possible with their cutting-edge products.With a strong focus on precision, efficiency, and reliability, CNC Wood has developed a reputation for delivering high-quality CNC machines that are tailored to meet the diverse needs of woodworkers around the world. The company's commitment to innovation and excellence has made them a trusted partner for many woodworking professionals, who rely on their advanced machinery to bring their creative visions to life.The latest range of CNC wood cutting machines from CNC Wood incorporates the latest technological advancements to ensure unparalleled performance and precision. These machines are designed to handle a wide range of woodworking tasks, from intricate carving and shaping to precise cutting and shaping of wood materials. With state-of-the-art controls and software, these machines offer woodworkers the ability to bring their designs to life with unparalleled accuracy and speed.One of the standout features of the new CNC wood cutting machines is their ability to work with a diverse range of wood materials, including hardwoods, softwoods, and engineered woods. This versatility makes them a valuable asset for woodworking professionals working on a wide range of projects, from furniture making to cabinetry and beyond. With the ability to handle complex designs and intricate details, these machines are poised to streamline the woodworking process and open up new possibilities for woodworkers.In addition to their cutting-edge technology, CNC Wood's new range of CNC wood cutting machines is designed with user-friendly features that make them accessible to woodworkers of all skill levels. With intuitive controls and easy-to-use software, these machines are designed to enhance the efficiency and productivity of woodworking operations, while also reducing the margin for error.Furthermore, CNC Wood offers comprehensive training and support for their products, ensuring that woodworkers can make the most of their investment. The company's commitment to customer satisfaction is reflected in their dedication to providing ongoing technical support and guidance, ensuring that their customers can maximize the potential of their CNC wood cutting machines.The introduction of CNC Wood's new range of CNC wood cutting machines is poised to redefine the woodworking industry, offering woodworkers a powerful tool to bring their creative visions to life with unparalleled precision and efficiency. By combining cutting-edge technology with user-friendly design, these machines are set to become an essential asset for woodworking professionals looking to elevate their craft and take their work to the next level.For woodworkers who are seeking to enhance their capabilities and explore new possibilities in woodworking, CNC Wood's new range of CNC wood cutting machines presents an exciting opportunity to unlock their full potential and soar to new heights of creativity and precision. With their unwavering commitment to excellence and innovation, CNC Wood continues to solidify its position as a leader in the woodworking machinery industry, empowering woodworkers to achieve their vision and bring their creations to life with unmatched precision and efficiency.

Affordable Mini Laser Cutting Machines for Small Businesses

Mini Laser Cutting Machines are quickly becoming a popular choice for small businesses and hobbyists who require precision cutting and engraving capabilities. These compact and versatile machines are capable of producing high-quality results, making them an ideal tool for a wide range of applications.{Company Name} is a leading manufacturer of Mini Laser Cutting Machines, known for their innovative and reliable products. With a strong focus on technological advancement and customer satisfaction, {Company Name} has established a reputation for delivering top-notch laser cutting solutions to their clients.These Mini Laser Cutting Machines are designed to be user-friendly and efficient, allowing users to create intricate designs with ease. Equipped with high-precision laser beams, these machines can cut through various materials such as wood, acrylic, leather, and even metal with unparalleled accuracy. This makes them an essential tool for businesses involved in signage manufacturing, crafting, jewelry making, and other industries that require intricate cutting and engraving.One of the key advantages of {Company Name}'s Mini Laser Cutting Machines is their compact size, which makes them suitable for small workshops and home-based businesses. Despite their small footprint, these machines deliver exceptional performance, making them an ideal choice for businesses with limited space.In addition to their cutting capabilities, these Mini Laser Cutting Machines are also equipped with engraving functions, allowing users to add personalized details to their products. Whether it's adding a company logo to a promotional item or engraving intricate designs onto jewelry pieces, these machines offer a high level of precision and flexibility.{Company Name} prides itself on offering comprehensive customer support and training programs for their Mini Laser Cutting Machines. This ensures that users are able to maximize the potential of their machines and produce high-quality results with ease. By providing ongoing technical support and resources, {Company Name} aims to empower their customers to achieve their creative and business goals.The versatility of {Company Name}'s Mini Laser Cutting Machines has attracted a wide range of clients, including small businesses, educational institutions, and individual hobbyists. Whether it's creating custom products for a small business or teaching students about design and fabrication, these machines offer endless possibilities for creativity and innovation.As technology continues to advance, Mini Laser Cutting Machines are expected to become an even more integral part of various industries. With their ability to produce precise, intricate designs at a rapid pace, these machines offer a cost-effective solution for businesses looking to streamline their production processes and offer unique, personalized products to their customers.{Company Name} remains committed to staying at the forefront of this evolving industry, continually refining and enhancing their Mini Laser Cutting Machines to meet the changing needs of their clients. By combining cutting-edge technology with a customer-centric approach, {Company Name} continues to be a trusted partner for businesses and individuals seeking reliable and efficient laser cutting solutions.In conclusion, the rise of Mini Laser Cutting Machines has brought about a significant shift in the way businesses and individuals approach design and fabrication. {Company Name} stands at the forefront of this burgeoning trend, offering innovative and reliable Mini Laser Cutting Machines that empower their clients to bring their creative visions to life. With a strong commitment to customer satisfaction and technological advancement, {Company Name} is well-positioned to continue leading the way in the Mini Laser Cutting Machine industry.

Top Multi Welding Machine: The Ultimate Welding Solution

The multi welding machine has become a vital tool in the welding industry, providing a convenient and efficient way to perform various types of welding processes. With the ability to perform multiple welding functions in one machine, it has revolutionized the way welding tasks are carried out, improving productivity, and reducing overall costs.One of the leading manufacturers of multi welding machines, {Company Name}, has been at the forefront of innovative welding technology for over a decade. The company takes pride in its commitment to providing high-quality, reliable, and versatile welding solutions to its customers across the globe. With state-of-the-art facilities and a team of experienced engineers and technicians, {Company Name} has established itself as a trusted and reputable name in the welding industry.The multi welding machine offered by {Company Name} is designed to cater to the diverse needs of welding professionals, offering a wide range of features and capabilities to meet various welding requirements. Whether it's MIG, TIG, or stick welding, the multi welding machine is capable of delivering exceptional performance and precision, making it an indispensable tool for welders in different sectors.One of the key advantages of the {Company Name} multi welding machine is its versatility and flexibility. With the ability to switch between different welding processes seamlessly, welders can complete a wide range of tasks without the need for multiple machines, saving time and effort. This not only streamlines the welding process but also enhances overall efficiency in the workshop.Furthermore, the multi welding machine from {Company Name} is built with durability and reliability in mind, capable of withstanding the rigors of heavy-duty industrial welding applications. The machine's robust construction and advanced technology ensure consistent performance, even in challenging working environments, making it a dependable asset for welders operating in demanding conditions.In addition to its superior performance, the {Company Name} multi welding machine is also designed with user convenience in mind. Intuitive controls, easy-to-read interfaces, and ergonomic designs make operating the machine straightforward and hassle-free, allowing welders to focus on their work without unnecessary complications.{Company Name} also places a strong emphasis on safety, ensuring that its multi welding machines are equipped with the latest safety features and mechanisms to protect both the user and the machine itself. With comprehensive safety protocols in place, welders can carry out their tasks with peace of mind, knowing that they are working with a reliable and secure welding system.The multi welding machine from {Company Name} is not only designed for professional welders but also caters to the needs of hobbyists and DIY enthusiasts. Its user-friendly interface and versatility make it an ideal choice for a wide range of welding applications, from automotive repairs to home improvement projects, providing an accessible and practical solution for users of all skill levels.As {Company Name} continues to innovate and evolve, it remains committed to delivering cutting-edge welding solutions that empower welders to achieve outstanding results. With a focus on quality, performance, and customer satisfaction, {Company Name} has solidified its position as a leading provider of multi welding machines, setting the benchmark for excellence in the welding industry.In conclusion, the {Company Name} multi welding machine represents a significant leap forward in welding technology, offering a comprehensive and efficient solution for welding professionals and enthusiasts alike. With its advanced features, robust construction, and user-friendly design, it has set a new standard for multi-process welding machines, demonstrating {Company Name}'s dedication to delivering top-quality welding solutions that meet the evolving needs of the industry.